Die casting and forging are the only two fabrication processes that significantly reshape metal by manipulating the shape at the interior level. These processes are used by manufacturers to develop metal components and products and are among the many processes that are used.

The decision of whether or not to perform die casting and forging operations in-house or to contract them out is available to manufacturers who require these services. It is possible that one of these options is more suitable for your company than the other, but this will depend on its goals. However, if lowering expenses, achieving shorter turnaround times, and gaining access to unusual metals are at the top of your list, you should think about contracting out for die casting and forging services.

Die casting and forging: advantages and typical products of each process

Die casting and forging are two processes that can be used to modify the internal structure of an alloy; however, these processes accomplish this goal in very different ways:

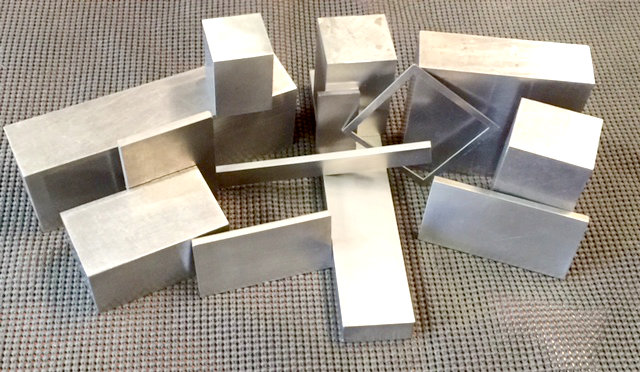

The process of die casting begins by melting an alloy by subjecting it to high temperatures. After that, the liquid metal is poured into a die, which is also known as a mold, and the die is shaped as the component that is desired.

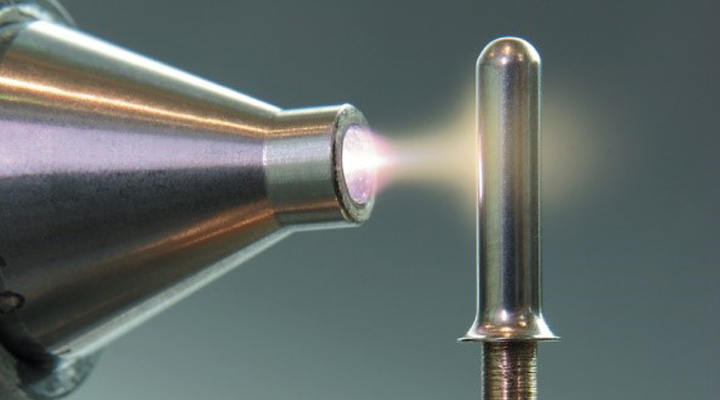

Forging begins by heating the alloy to a temperature that enables the metal to be adjusted by force, causing the alloy to change shape while it is still in a solid state. This allows the metal to be shaped into the desired form without the metal having to be molten.

Both of these fields have deep roots in their respective communities and remain dynamic today:

The recent regulations that require vehicles to emit fewer emissions and function with greater energy efficiency are a primary factor driving the expansion of the die casting industry. This growth is primarily being driven by the automotive industry.

The growth of the forging industry is primarily driven by the oil and gas industry, which requires components and products to have high overall fatigue strength. As a result, the forging industry is experiencing significant expansion.

Die casting and forging both have a number of advantages, such as the ability to create complex components, flexible quantities, high strength and quality, and low operating costs. However, these processes also have higher initial costs, secondary finishing processes, and potential limitations due to the complexity of some components.

In addition, there is a possibility of contamination occurring during the process of die casting when the metal is in a liquid state. If the component is not stored in a location that has adequate temperature regulation, then it is possible that certain defects, such as interior tears or cracks, will develop.

When you work with VPIC Group, you can expect to receive precision component manufacturing of the highest quality available in the market today.

Die casting and forging services can be outsourced, which has a number of advantages.

An outsourced original equipment manufacturer (OEM) supplier that implements quality assurance, uses the most recent technology, and manufactures with state-of-the-art equipment can help mitigate a good number of the drawbacks that were discussed in the previous section.

Companies can reap the following benefits from forming partnerships with original equipment manufacturers:

Capacity that is both Increased and Flexible

Working with an OEM supplier is advantageous for a number of reasons, one of which is the ability of that supplier to be flexible regarding the types of components it can manufacture. OEMs can help eliminate bottlenecks, grow with your company as a strategic partner, and assist as temporary support when your facilities are stretched to their capacity if they have greater production capabilities than your company does.

Quality Improvements Made to the Components

OEM suppliers staff their operations with full teams of engineers and technicians who have received extensive training and are focused on die casting and forging. In addition, entire teams are focused on improving both the management of projects and the manufacturing processes in order to produce a business that is more efficient financially.

Reduced Expenditures

Manufacturing goods in-house can be hampered significantly by the high overhead costs involved. By using outsourcing, businesses are able to gain access to investments that they would be required to make if they ran their operations in-house. These investments include staffing, material resourcing, the purchase of equipment, and quality control.

New viewpoints and insights

When a company forms a partnership with an original equipment manufacturer (OEM) supplier that has been in business for many decades, that company's team is able to provide experience in many different types of products and industries, bringing to the table new ideas and attempting to circumvent bottlenecks with novel approaches.

More Rapid Turnaround Times

OEM suppliers are able to maintain appropriate inventory levels and put logistics strategies into action in order to deliver short lead times. This is in addition to optimizing the manufacturing processes themselves.

Quality Control and Assurance

OEM suppliers are able to provide expert quality assurance services that implement standards to reduce risk while simultaneously ensuring that their products and components are of the highest quality.